About ALPHA

Production Technology

Superior manufacturing technology

ALPHA Corporation applies advanced information-processing systems in all processes from order receipt through shipping. By means of comprehensive computerized online control, where Planning, R&D, Sales and Production are connected by network, order-intake planning, production planning, progress control and shipping operation are rationally controlled. The integrated management from manufacturing to sipping enables us to constantly deliver products of high quality to customers.

Dies/equipment for casting & molding

Production equipment for processing & assembly

Plastic molding (for painted, plated and molded-in-color parts)

- Adoption of gas-assisted injection (AGI) molding machine

Dies/equipment for casting & molding - Automated insert molding using robot

Insert molding with vertical molding machine

Diecasting (Zinc diecasting)

- Automated line directly connecting casting through machining/circumferential finish

Press (Key plate, Tumbler, Cylinder cap)

Blow molding machine

Key grooving (for key plates)

Key cutting

CNC automatic lathe

Dimple key cutting

-

Key way cutter

Painting (for Zinc diecast and plastic molded parts)

- Urethane painting: capable of processing with 20 to 30 colors/day by automatic color changing

Plating (plating for plastic material)

- Gloss chrome plating

- Velour plating

- Matt chrome plating

-

Fully automated electrostatic painting equipment

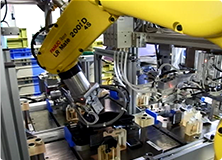

Automated assembly line

- Production with house-made automatic assembly machine utilizing robots

Shutter assembly

- Assemble cylinder shutter with automatic machine

Tumbler assembly

- After reading keycodes, automatically assemble tumblers into the cylinder

-

Automatic assembly machine (HANDLE)